THE FUTURE OF SUSTAINABLE AVIATION FUELS

Popular

What we do

TACKLING A BARRIER TO FLYING GREEN

Sustainable Aviation Fuels (SAF) are blended in different types and ratios, due to varying airlines commitment, process technology and market legislations. Adding to complexity, SAF are currently processed at refineries of fixed geographies, depending on origin, requiring additional logistics cost, time and carbon footprint. This makes it costly, less accessible and available to some airports.

HAT WE DO

We’re Changing the Way SAF is Delivered to Airports

SAF is the most viable drop-in solution to flying green today. But, the current supply chain has to be better integrated.

We resolve this with last-mile blending and distribution directly to airports, with our patented last-mile technologies.

Company's story

Our Specialty

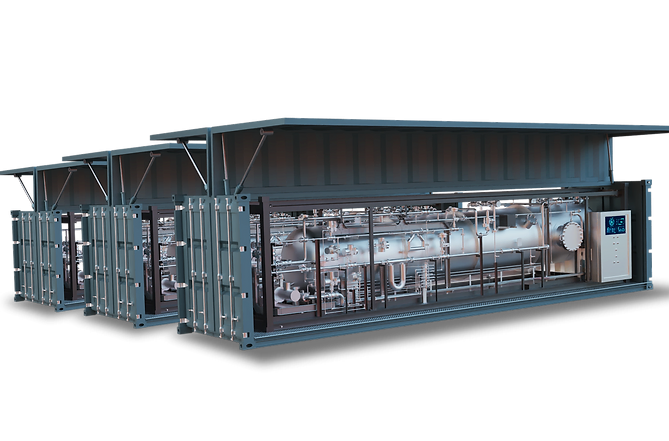

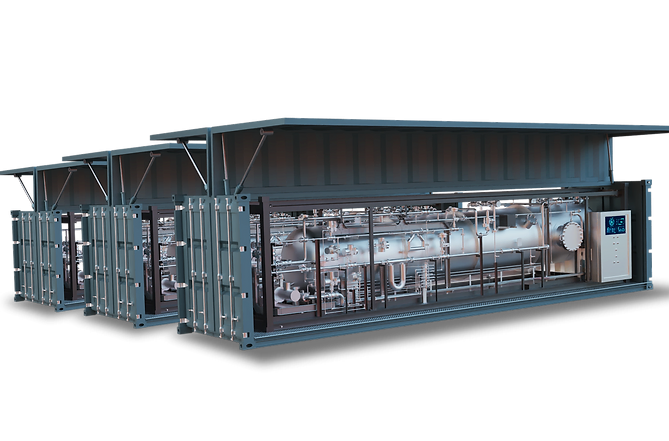

We enable last-mile SAF blends with our AlphaLite Technologies.

50%

BLEND RATIOS

(In accordance to ICAO specifications)

20 min.

BLEND TIME

(Certified to ASTM D1655 standards)

3 hrs

PRODUCT READY BEFORE DEPARTURE

0 CAPEX NEEDED

Zero CAPEX needed, we deploy our AlphaLite and tie-in with existing fuel farms. The AlphaLite is designed to be easily integratable with existing site operations, and manufacture SAF blend products in accordance to ASTM D1655 quality standards.

50%

BLEND RATIOS

(In accordance to ICAO specifications)

20 min.

BLEND TIME

(Certified to ASTM D1655 standards)

3 hrs

PRODUCT READY BEFORE DEPARTURE

0 CAPEX NEEDED

Zero CAPEX needed, we deploy our AlphaLite and tie-in with existing fuel farms. The AlphaLite is designed to be easily integratable with existing site operations, and manufacture SAF blend products in accordance to ASTM D1655 quality standards.

Our story

WHY FLYORO

A Different Approach, Using a New Method of Blend Technologies.

Conventional blending facilities are heavy on CAPEX, OPEX and asset-intensive, yet only offers limited geographical coverage. Our patented technologies allow SAF blends to be directly manufactured for airports, simplifying the supply chain, logistic spends, inventory and carbon footprint.

With our advantage in technology cost, scale-up flexibility and rapid deployment time, we can pass on these savings to airlines and passengers - reducing the cost barrier towards flying green.

A Different Approach, Using a New Method of Blend Technologies.

Conventional blending facilities are heavy on CAPEX, OPEX and asset-intensive, yet only offers limited geographical coverage. Our patented technologies allow SAF blends to be directly manufactured for airports, simplifying the supply chain, logistic spends, inventory and carbon footprint.

With our advantage in technology cost, scale-up flexibility and rapid deployment time, we can pass on these savings to airlines and passengers - reducing the cost barrier towards flying green.

General Information

Gallery