Injection moldable advanced wood plastic composite【i-WPC】

Notice: Undefined index: options in /home/xs999583/sustainaseed.net/public_html/db.sustainaseed.net/wp-content/themes/dlist/inc/directorist-support.php on line 318

Notice: Trying to access array offset on value of type null in /home/xs999583/sustainaseed.net/public_html/db.sustainaseed.net/wp-content/themes/dlist/inc/directorist-support.php on line 318

Notice: Trying to access array offset on value of type null in /home/xs999583/sustainaseed.net/public_html/db.sustainaseed.net/wp-content/themes/dlist/inc/directorist-support.php on line 318

What we do

“i-WPC”

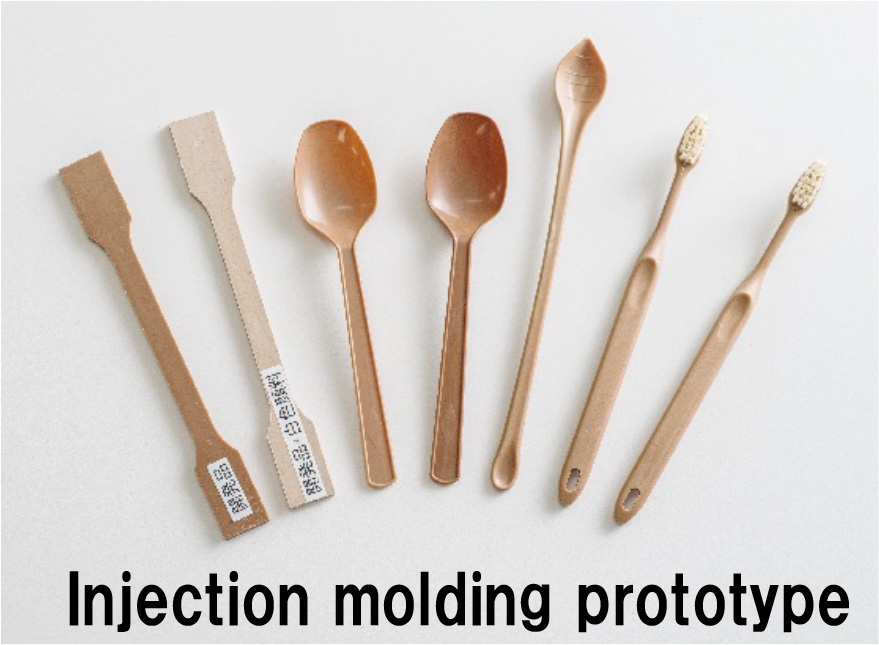

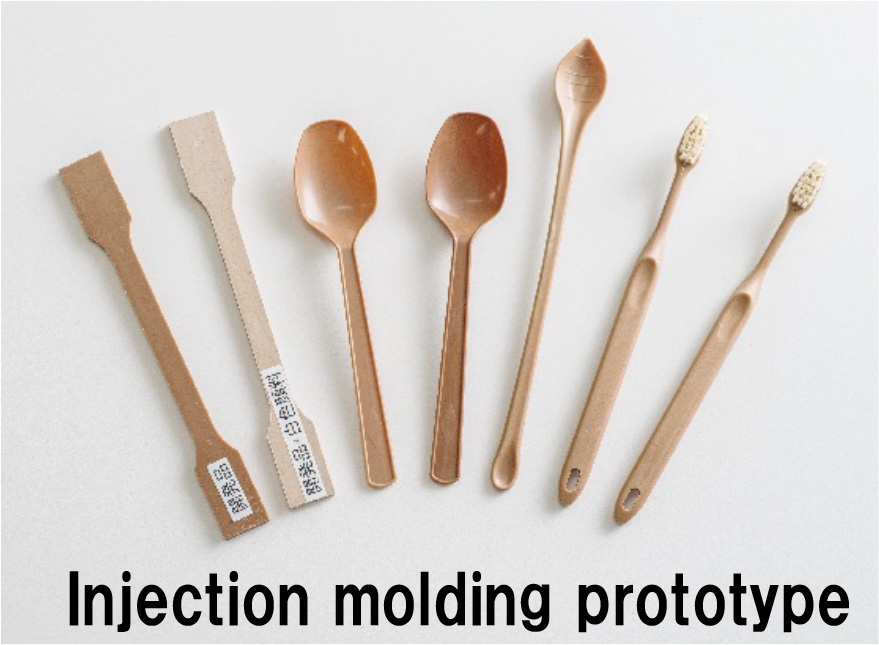

Until now, composite materials of wood flour and plastic (wood plastic material, WPC) have been used in wood deck and park facilities as anti-septic woods, but they were manufactured in long bar-shape with same cross-sectional shape by the method called “extrusion molding”. On the other hand, there is a method suitable for mass-production called “injection molding”, that injects heat-melted resin into a metal mold as a method of making a form such as a bucket or a toy. But it has been considered remarkably difficult to injection mold with wood plastic composite, and there has been almost nothing produced commercially.

Usually, WPC’s melt viscosity is remarkably large, if you raise the molding temperature at 200℃ higher in order to reduce the melt viscosity, wood components will thermally decompose, resulting in bad odors and burns resulting in blackening. There are many difficulties to realize commercial production by injection molding. The manufacturing technology that we have established for WPC allows injection molding, which up to now has been regarded as impossible. “i-WPC” can be molded with general-purpose plastic injection molding machines and metal mold.

Company's story

We will develop new complex technology and give shape to our dreams. You can anticipate something special. We will develop composite materials that give users intuitive ideas. In addition, we will create composite materials that users can easily understand in terms of the kinds of effect they have and why they have such characteristics. In the future, we would like to create something useful for the world by exercising creative ingenuity with users.

General Information

Gallery