Clean liquid fuel for heavy industry

Notice: Undefined index: options in /home/xs999583/sustainaseed.net/public_html/db.sustainaseed.net/wp-content/themes/dlist/inc/directorist-support.php on line 318

Notice: Trying to access array offset on value of type null in /home/xs999583/sustainaseed.net/public_html/db.sustainaseed.net/wp-content/themes/dlist/inc/directorist-support.php on line 318

Notice: Trying to access array offset on value of type null in /home/xs999583/sustainaseed.net/public_html/db.sustainaseed.net/wp-content/themes/dlist/inc/directorist-support.php on line 318

What we do

Liquium is revolutionising the ammonia production process helping it

align with renewable energy, lower the cost of production and operation & have a broader scale for more applications.

Company's story

Our Specialty

THE PROBLEM

Ammonia has the highest energy density for a zero carbon fuel, however it is not a ‘green’ chemical – Currently it has a significant carbon footprint due to the fossil fuel source of the energy and hydrogen required to make ammonia.

The ammonia landscape has been built on fossil fuel utilisation for the past 100 years. But the climate crisis is dictating a need for change to remove carbon emissions. Fortunately, the ammonia sector can remove fossil fuels through the adoption of renewable electricity and green hydrogen. This provides a carbon zero set of building blocks to produce ammonia. However, the intermittency of renewable energy and the difficulties associated with the handling and storage of hydrogen at an industrial scale present new challenges to the ammonia sector.

Green ammonia production has to be adopted at 3x the current scale in the next 30 years to help address the decarbonisation targets.

- Built at scale (small to large)

- Lower cost (CapEx and OpEx)

- Agile operation

- Increased renewable energy utilisation efficiency

- Minimize hydrogen storage and buffering

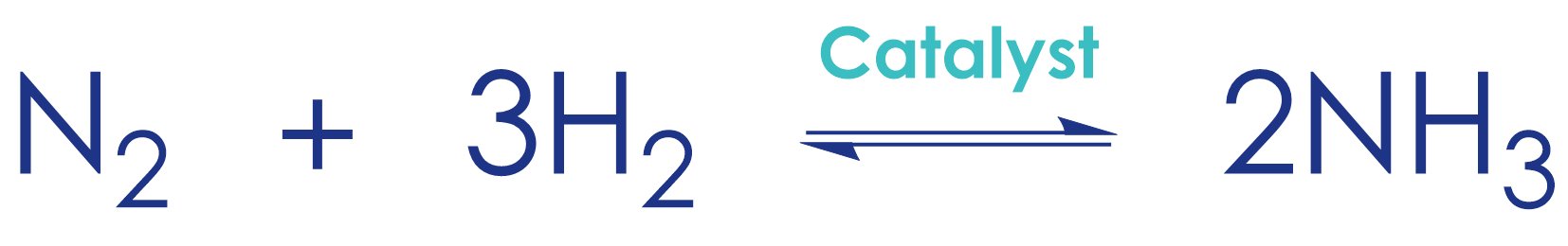

Liquium’s solution to the upcoming ammonia revolution is at the heart of the process - the catalyst.

Our novel catalysts have industrially relevant chemical and physical properties, scalable manufacturing and world-class low activation energies - aligning to a milder ammonia production process. In addition, Liquium’s ammonia reaction follows the same proven chemical engineering design for a thermochemical reaction, i.e. the Haber-Bosch process (just under milder conditions). This eliminates a major proportion of engineering risk and development for scaling this process to industrially relevant operations.

Ammonia has the highest energy density for a zero carbon fuel, however it is not a ‘green’ chemical – Currently it has a significant carbon footprint due to the fossil fuel source of the energy and hydrogen required to make ammonia.

The ammonia landscape has been built on fossil fuel utilisation for the past 100 years. But the climate crisis is dictating a need for change to remove carbon emissions. Fortunately, the ammonia sector can remove fossil fuels through the adoption of renewable electricity and green hydrogen. This provides a carbon zero set of building blocks to produce ammonia. However, the intermittency of renewable energy and the difficulties associated with the handling and storage of hydrogen at an industrial scale present new challenges to the ammonia sector.

Green ammonia production has to be adopted at 3x the current scale in the next 30 years to help address the decarbonisation targets.

- Built at scale (small to large)

- Lower cost (CapEx and OpEx)

- Agile operation

- Increased renewable energy utilisation efficiency

- Minimize hydrogen storage and buffering

Liquium’s solution to the upcoming ammonia revolution is at the heart of the process - the catalyst.

Our novel catalysts have industrially relevant chemical and physical properties, scalable manufacturing and world-class low activation energies - aligning to a milder ammonia production process. In addition, Liquium’s ammonia reaction follows the same proven chemical engineering design for a thermochemical reaction, i.e. the Haber-Bosch process (just under milder conditions). This eliminates a major proportion of engineering risk and development for scaling this process to industrially relevant operations.

Our story

From beginnings as a research discovery at Te Herenga Waka—Victoria University of Wellington, Liquium has reimagined a future where clean ammonia will be pivotal to decarbonisation and energy security.

We believe we can play a critical role in the uptake of green ammonia as the next clean liquid fuel to decarbonise heavy industries

We believe we can play a critical role in the uptake of green ammonia as the next clean liquid fuel to decarbonise heavy industries

General Information

Gallery