ELECTROLYSIS AT ITS BEST

Notice: Undefined index: options in /home/xs999583/sustainaseed.net/public_html/db.sustainaseed.net/wp-content/themes/dlist/inc/directorist-support.php on line 318

Notice: Trying to access array offset on value of type null in /home/xs999583/sustainaseed.net/public_html/db.sustainaseed.net/wp-content/themes/dlist/inc/directorist-support.php on line 318

Notice: Trying to access array offset on value of type null in /home/xs999583/sustainaseed.net/public_html/db.sustainaseed.net/wp-content/themes/dlist/inc/directorist-support.php on line 318

What we do

Hydrogen produced from renewable electricity substitutes fossil fuels and substantially lowers CO2 emissions across all sectors. As industrial feedstock, hydrogen is used for the refining of crude oil, iron and steelmaking as well as the production of fertilizers and of numerous chemical products. As energy carrier, renewable hydrogen decarbonizes mobility, power and heat supply.

HYDROGEN ELECTROLYSIS SOLUTIONS

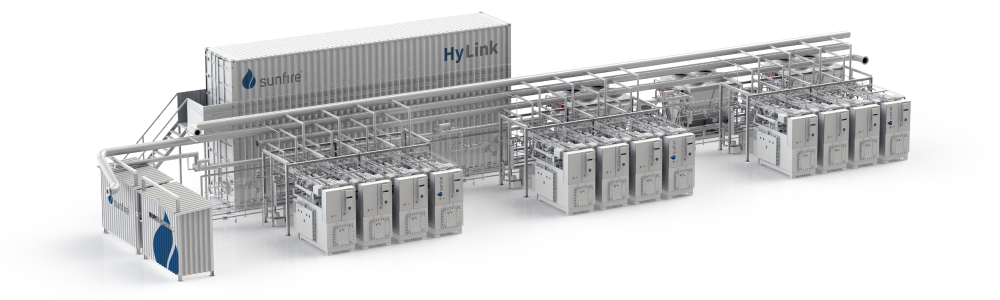

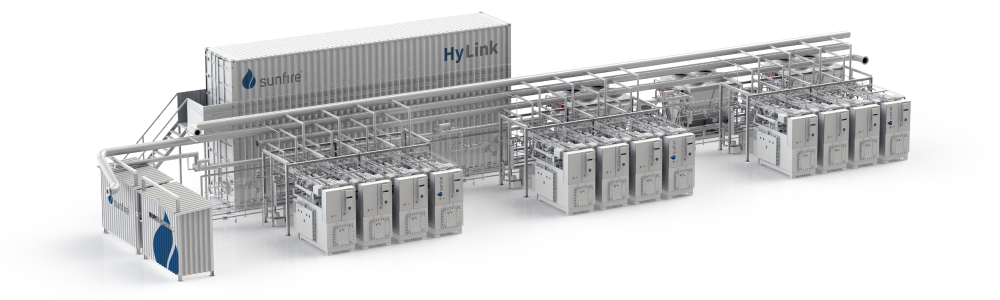

Sunfire’s HyLink electrolyzers are the optimal solution for your renewable hydrogen project. Based on Alkaline and solid oxide (SOEC) technologies, our electrolyzers are tailored to the unique requirements of your industry and local environment. Whether as standalone or hybrid electrolysis solution, we turn your hydrogen plans into reality.

SUNFIRE-HYLINK ALKALINE

Sunfire’s ultra-reliable pressurized Alkaline electrolyzer is optimal for applications without or with limited steam availability. With a proven stack lifetime of at least 90,000 operating hours, the electrolyzer is our established solution for renewable hydrogen production.

CORE ADVANTAGES

+ Robustness: Proven technology with demonstrated system runtime of more than 20 years

+ CAPEX: Lowest electrolyzer costs reduce capital requirements

+ Pressure: Renewable hydrogen is delivered at a pressure of up to 30 bar(g)

+ Scalability: Modular 10 MW stack design enables effective scaling to large electrolysis capacities

+ Adaptability: Easy integration into any environment – whether industrial or greenfield

SUNFIRE-HYLINK SOEC

Sunfire’s high temperature, solid oxide cell electrolyzer is the superior electrolysis solution for industrial applications when steam is available. Running at 850 °C, our SOEC utilizes industrial off-heat to process water steam to hydrogen at highest conversion efficiencies.

The electrolyzer follows a modular system design. One system produces 750 Nm³/h hydrogen with a power consumption of 3.6 kWh/Nm³.

CORE ADVANTAGES

+ Steam electrolysis: Utilization of industrial off-heat as steam reduces electricity demand

+ Efficiency: Market-leading efficiency (84 %LHV TO AC) yields lowest hydrogen costs

+ Reliability: Certified electrolyzers with proven long-term operation

+ Flexibility: Modular design simplifies scaling to any desired electrolysis capacity

+ Sustainability: No use of PGM-based materials in electrolyzer production

Company's story

Sunfire’s ultra-reliable pressurized Alkaline electrolyzer is optimal for applications without or with limited steam availability. With a proven stack lifetime of at least 90,000 operating hours, the electrolyzer is our established solution for renewable hydrogen productionn.

The electrolyzer has a scalable system design. One system produces 2165 Nm³/h hydrogen at 30 bar(g) with a power consumption of 4.7 kWh/Nm³.

General Information

Gallery